2024 - Tsinghua Summer Internship

I spent my summer at Tsinghua University in a lab associated with one of their departments of engineering. I worked on a team with one other intern, and we were fortunate to be supervised by Professor Huirong Le and his research students. Below I summarize our project.

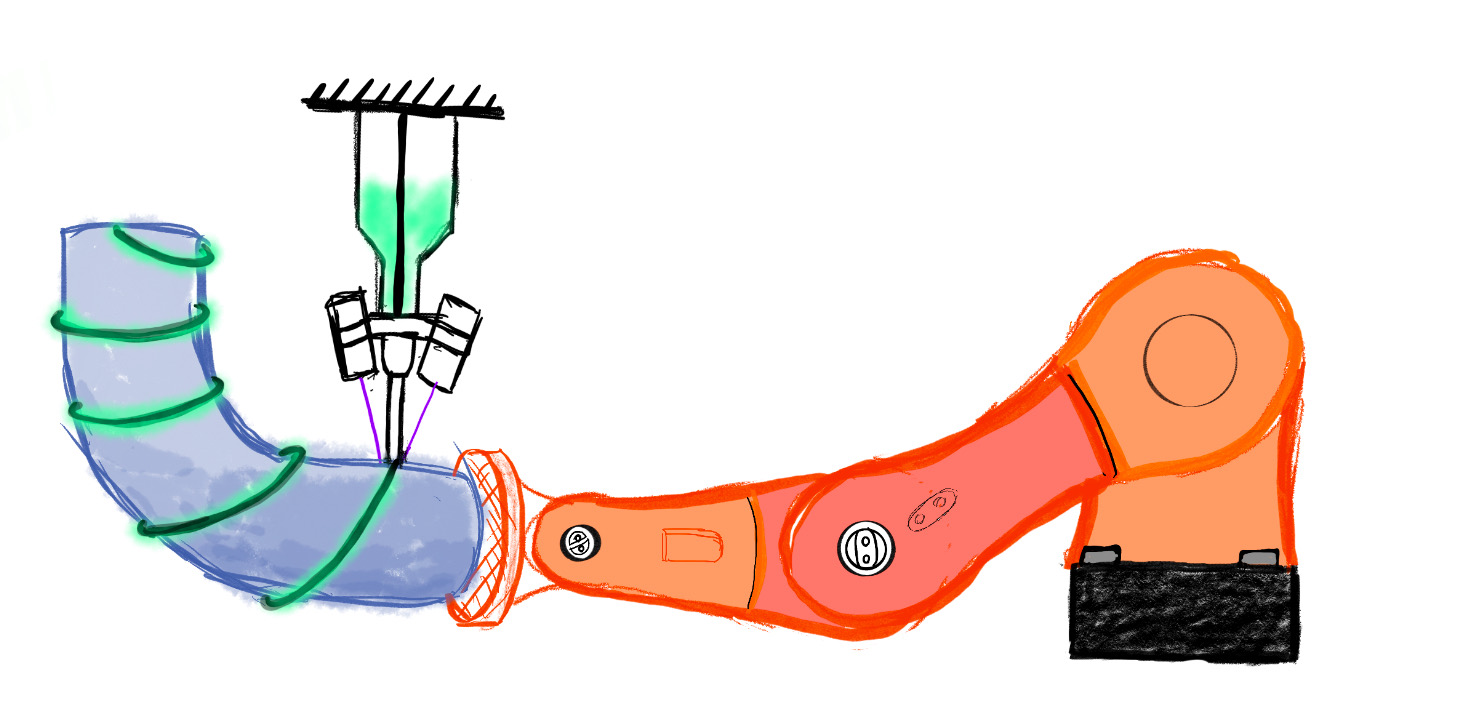

Conventional 3D printing involves depositing material one layer after another. One result of this is weak strength between layers. Meanwhile, multi‑axis robotic printing uses robotic arms to the printed part and/or nozzle from which material is extruded. This makes many more complex geometries printable. Furthermore, continuous carbon fiber is a material that offers high stiffness and strength along the fiber axis. We propose to print continuous carbon fiber onto the surface of parts made with conventional printers. We optimize a path for the fiber, such that it aligns with the principle stress directions of the part under a specified load. In our design, we perform FEA for stress analysis, neural optimization of a scalar field, and then a number of further steps to make a printable toolpath. We transform the toolpaths into movements for a KUKA robot that holds the printed part. A custom extruder head prints the fiber, dispenses resin and cures it with a laser.